Crazing on Single Ply Roofing

Crazing is the development of a multitude of very fine cracks on single ply membranes such as EPDM, TPO and PVC. It is similar to alligatoring.

Plasticizers are added to PVC roofs to make them softer and more flexible. Over time, the plasticizers migrate out of the roof. Heat and pressure can speed up the process.

In the past, the loss of the plasticizers in un-reinforced membranes caused systemic failures as embrittlement caused the membranes to shatter during cold weather. Now, all PVC membranes are reinforced, and new formulations minimize the loss of plasticizers from the membrane. To add to the confusion, there are a lot of different formulations in the market.

Unless good records are kept, it is oftentimes difficult to determine if your roof has the new or old formulation. If your PVC roof is chalky and there is visible crazing all over the roof, we recommend replacing the roof instead of restoring it.

Crazing on single ply membranes occur on the top layer above the reinforcing mesh. If deterioration continues, the craze can become a crack which results in roof failure. Widespread crazing allows water to penetrate the membrane causing roof leaks which can be difficult to isolate and repair.

Stages

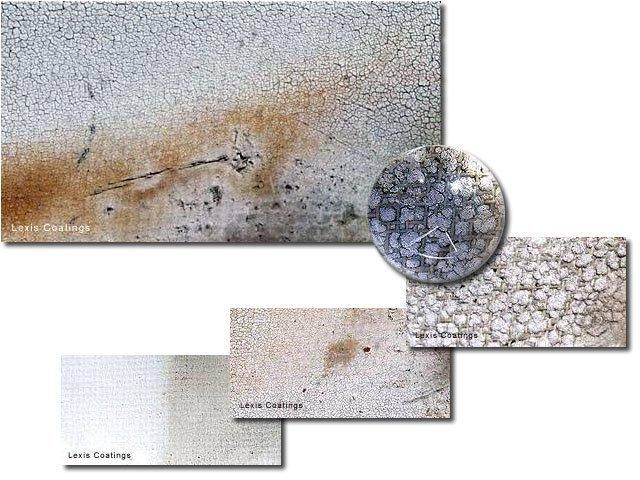

Mild Crazing

A single membrane ply in the beginning stages of crazing. It still appears in good condition but the surface is chalky. Pressure washing cleans the roof but does not eliminate all the chalking.

Moderate Crazing

A single ply membrane in moderate stages of crazing. A roof coating needs to be applied immediately to restore this roof.

Severe Crazing

This roof has been neglected and crazing has progressed to membrane cracking. The reinforcing fibers are now brittle and this section should be replaced. This is a failed roof and can no longer be restored.

Extend Roof Life with Elastomeric Coatings

Elastomeric roof coatings can be used to restore a crazed roof in good condition. Depending on the your roofs existing condition and configuration, elastomeric roof restoration can save up to 50% over re-roofing costs. The money spent on restoration is not a capital investment and does not need to be amortized.